Products and SHARP SHAPESM Services

Sharp Shape provides AOMS Systems through the integration of our trademarked AOMS CAD/CAM software, our 3D scanners, and our setup/training. AOMS software has three flavors, i.e. positive mold, orthotic shell, and footbed insole. AOMS System is self-sufficient, compared with some packages of scanner-only, or software-only. Although we do not carry CNC machines and 3D printers, we treat them as "off-the-shelf" products and they can be purchased from customers’ territories with our consultation. We provide services to integrate the AOMS systems onsite and to provide remote support afterwards.

A comprehensive product and service line of orthotic automation has been formed since 1993.

Our system features can be found in this document: AOMS Capacity

and in items listed below.

AOMS TOT CNC (New 2025):

Many foot orthotic labs still prefer CNC-milling to 3D-printing. There are many reasons. Facing this reality, recently we developed a new method still using CNC machines, but incorporating the latest mobile foot scanning technology. It is one of a kind and it is a break-through. Orthotics are fully customized and our approach is easy to understand. Click here to check it out.

AOMS 3DPRN app (New 2024):

We are proudly introducing another innovative orthotic design approach. To design a pair of foot orthotic, you just need an iPad or an iPhone with the AOMS 3DPRN app on it. To have a pair of orthotic made, you just need to send out the STL files to a contracted 3D printing facility. For more information, please visit: AOMS 3DPRN app.

AOMS TOT sr (New 2023):

We are excited to introduce our newly designed AOMS TOT sr. Information can be found from the AOMS TOT sr web page. So what's good about AOMS TOT sr, compared with the previous AOMS TOT jr? Well, it is about scanning speed, tracking stability, broader device compatibility, and smoothness of data. This app can be used in our AOMS orthotic production systems. For this app, you must have an Apple device which has the TrueDepth camera inside. Ask us for more details.

AOMS TOT jr (New update 2022):

AOMS TOT jr is a relatively new foot scanning approach. Our previous AOMS TOT app is used on iPad with the Structure Sensor attached, while the AOMS TOT jr is operated without any attachments. It makes a much smaller and more reliable hardware. Recent AOMS TOT jr app update makes it more powerful. Information can be found from the AOMS TOT jr info page. If you are involved in using this technology, you can also visit the AOMS TOT jr tutorial page.

AOMS TOT Fit (New 2021):

During the past several months when the world was covered by Covid-19 pandemic, we have been busy in developing a new product. It is called AOMS TOT Fit. Now we have the first release of it. Information can be found from the AOMS TOT Fit info page. If you are involved in using this technology, you can also visit the AOMS TOT Fit implementations page.

AOMS 3DPRN (New 2020):

3D printed orthotics gradually gets industry’s attention. Our AOMS 3DPRN software has been in beta-testing phase for a couple of years. Some labs are using it. Information can be found from the AOMS 3DPRN info link.

AOMS TOT:

A mobile, handheld foot scanner and orthotic manufacturing solution package, just out of beta testing. For information regarding this wireless iPad foot scanner and the orthotic production system, please visit the AOMS TOT information page. If you want to set up / install the iPad foot scanner and the AOMS TOT app, please visit the system requirements, setup and tutorial page.

AOMS TOT MILL - experimental orthotic manufacturing process:

AOMS TOT MILL is a new automated orthotic manufacturing process. It emphasizes simplicity with the latest new technologies. Click the AOMS TOT MILL info page for details.

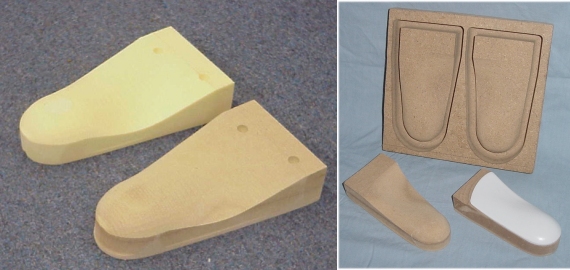

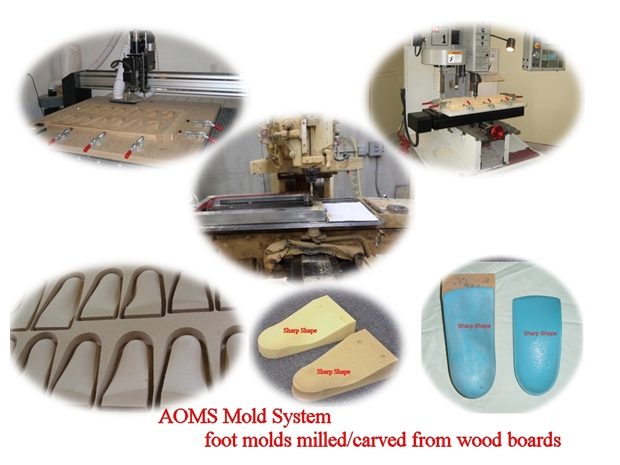

AOMS Mold System - foot molds milled/carved from wood boards:

AOMS Mold System is the most popular system because of its versatility and easiness to learn and to operate. All kinds of materials, like polypropylene, polyethylene, graphite, cork, etc. can be used with the milled molds. You can click the following picture to view a larger version.

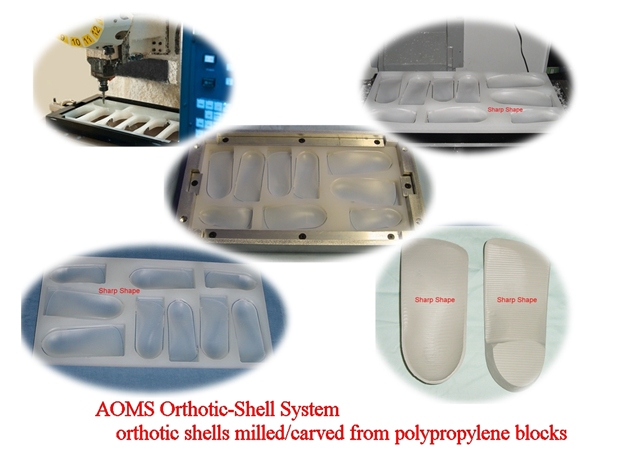

AOMS Orthotic-Shell System - orthotic shells milled/carved from polypropylene blocks:

AOMS Orthotic-Shell System is the most labor-saving system because it skips the process of thermo-forming plastic on top of a positive mold. Minimal labor remains after milling.

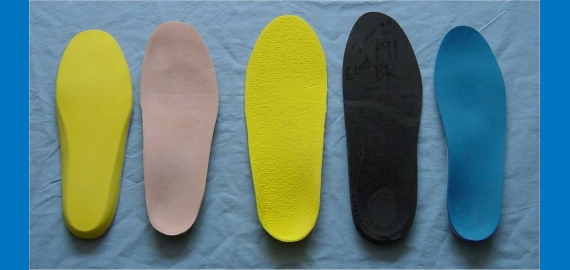

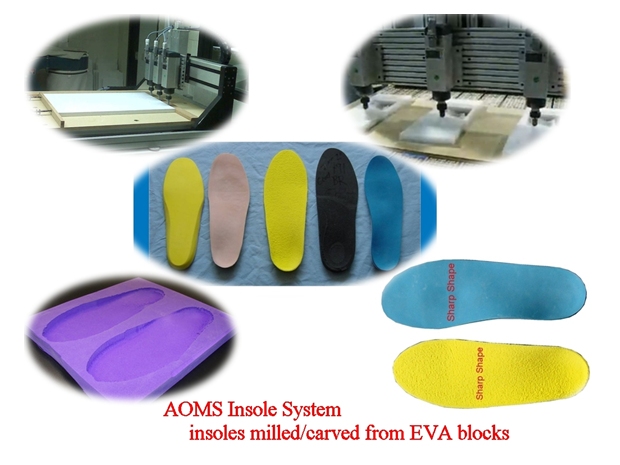

AOMS Insole System - insoles milled/carved from EVA sheets:

AOMS Insole System is getting more popular because more and more shoe businesses are getting into the custom orthotic service, and more and more orthotic labs are getting into the shoe business. Custom shoe inserts can be made from the milling system. If you choose, three spindle heads can be mounted on the CNC router and three identical pairs of insoles can be carved at the same time. It increases productivity.

Sharp Shape 3D Laser Foot Scanner, Model USB3D

This is electronic imaging equipment designed for podiatrists working with patients' feet. The current podiatric/clinic 3D digital foot scanner is the third generation of the product line. It is accurate and compatible with our CAD/CAM foot orthotic system. It is part of our orthotic system solutions.

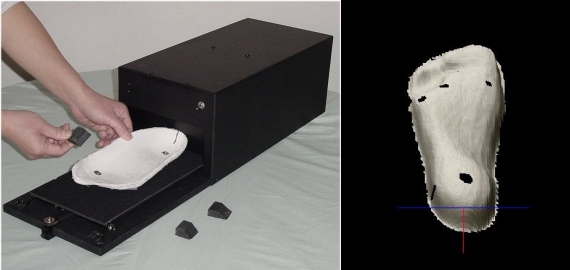

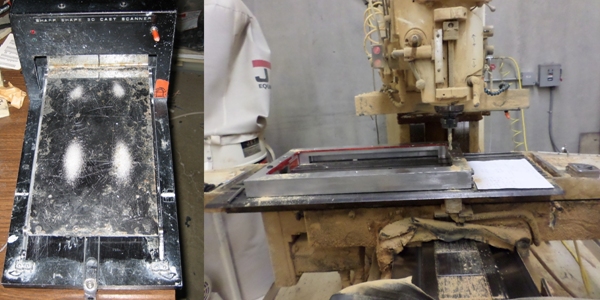

Sharp Shape 3D Laser Cast Scanner, Model USBLSX

This is electronic imaging equipment designed for the labs or podiatry groups who normally work with patients' negative foot casts. Impression foam can also be scanned with certain limitations. It has been proven to be accurate and reliable in many orthotic labs.

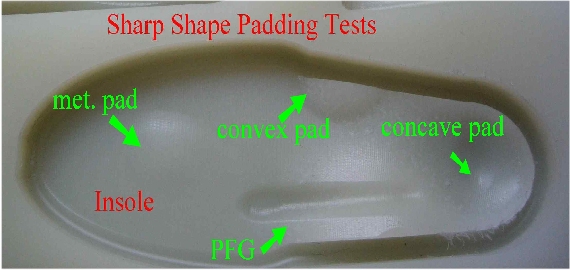

Semi-Custom and Prefab Orthotic Design Package

For use in labs and doctor’s offices, this serves as an alternative subsystem to make devices to relieve patients' minor symptoms that do not justify a more costly fully customized device. It is also meant to reduce costs in orthotic production. This is a newly developed package. Please make an inquiry if you are interested.

Matching System

Evolved from the above package, this matching system has emerged. This system utilizes our scanners and the customers' existing orthotic library to produce matches using a software package developed by us. It saves the expenses on mill and time in cast corrections. We have installed three such systems. Please contact us for details.

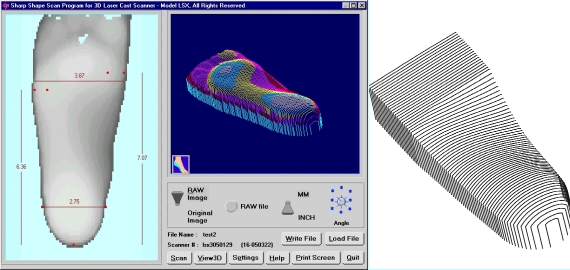

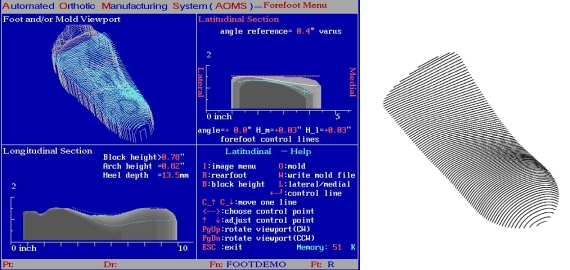

CAD (Computer Aided Design) Program in AOMS

Using this program, the user is able to apply biomechanical corrections and controls to the scanned casts according to doctors' prescriptions. From a generic correction base, we customize our program to the correction types preferred. It is the most widely used software in all orthotic systems.

CAM (Computer Aided Manufacturing) Program in AOMS

Using this program, the user is able to schedule the placement of devices on the mill and generate a milling toolpath file. We customize our program to almost any CNC mill or router that you choose for your system. It has been adapted to many types of orthotic mills and routers.

Installation and Training

Installation and training are provided at the customer's location. A setup trip is used to integrate the whole system and to provide adequate training for the operator(s). If you choose a simple solution, such as a hub system, the setup trip may be waived. We have set up many custom foot wood-mold production systems, custom polypropylene orthotic shell production systems, and custom EVA insole manufacturing systems. After 10 years since the business establishment in 1993, AOMS became the most popular and advanced orthotic fabrication system.

Consultation

Provided for choosing the market products, such as CNC mills/routers, computers, and networks. We also help you on your own research and development.

=======================================================

Sharp Shape Products are heavily used in AOMS systems

We do not charge royalty from our AOMS 1.0 systems. The more you use the system, the more you benefit from the system. Besides the story that we heard from one of our lab customers that they have replaced their keyboards six times for the AOMS cast correction computer (see home page), we have the following photos to show how a Sharp Shape cast scanner has been heavily used and how a CNC mill has been heavily used in the AOMS systems.

Scan Program Tutorial: Processing Functions

Click the Play sign to play. Need speakers for sound. Tested on Google Chrome and Apple iPad.

=======================================================

Scanner Operation Tutorial

If you need anything, Contact Us.