AOMS TOT Information

Titles:

Titles:

What is the AOMS TOT technology package about?

What is our motive to create AOMS TOT?

Why use AOMS TOT, and not other approaches?

What is the AOMS TOT iOS app about?

What is the conversion/processing software about?

Why is our conversion/processing software the best?

What is our history & views on the AOMS TOT project?

What are the major challenges to AOMS TOT?

What are the Pros and Cons of AOMS TOT?

What are our efforts towards better images & orthotics?

Why are all iPad scanners not made the same?

Why not create an app for the smartphone, like an iPhone?

What are the cost comparisons on AOMS TOT?

How to start the AOMS TOT in action?

What is ahead of us with AOMS TOT?

How do we react to the "threatening" technologies?

Notes to the readers

(Important Notes)

What is the AOMS TOT technology package about? Back to Titles

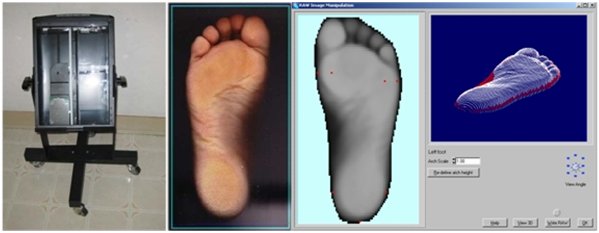

AOMS TOT ™ is a technology package, which includes an Apple iPad, a small 3D sensor called the Structure Sensor, a Sharp Shape customized iOS app (AOMS TOT), and a Sharp Shape specially designed Microsoft Windows conversion/processing program. With the many AOMS systems that are already in place, AOMT TOT technology provides a custom foot orthotic production system with the most affordable true 3D iPad foot scanner with mobility and versatility. Behind the AOMS TOT package, the AOMS system is the backbone for making custom foot orthoses with the images generated from the AOMS TOT. AOMS stands for “Automated Orthotic Manufacturing System” and TOT stands for “Transformation of Technology.”

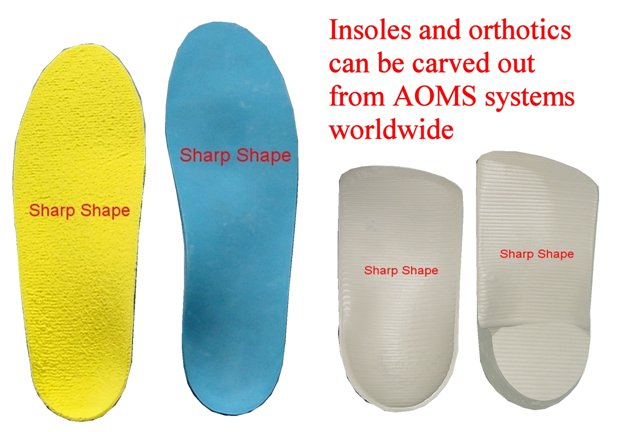

Sharp Shape AOMS TOT is about foot-scanning in a new way.

Sharp Shape AOMS TOT is also about orthotic-manufacturing.

What is our motive to create AOMS TOT? Back to Titles

Sharp Shape has been installing AOMS® systems and making 3D foot/cast scanners for more than 20 years. During this period, many customers asked us for portable, handheld, wireless, low-cost 3D foot scanners and for the ability to link scanners with AOMS systems. The 3D scanning tech world has made significant progress in the last 5 years. A big improvement is the ability to link scanners with mobile devices. After years of our R&D, we have come up with a new approach that satisfies our customers’ needs. A 3D laser foot scanner package well under $1,000 is a reality now. Our regular full-size foot scanner (USB3D) came to the market in the early years as the first of its kind and then similar designs followed. Technologies are dynamic. Now we feel wireless, handheld, mobile foot scanners are most welcomed by the majority of users because of their versatility and low cost.

The iPad scanner fits in when bulky and expensive scanners are not required.

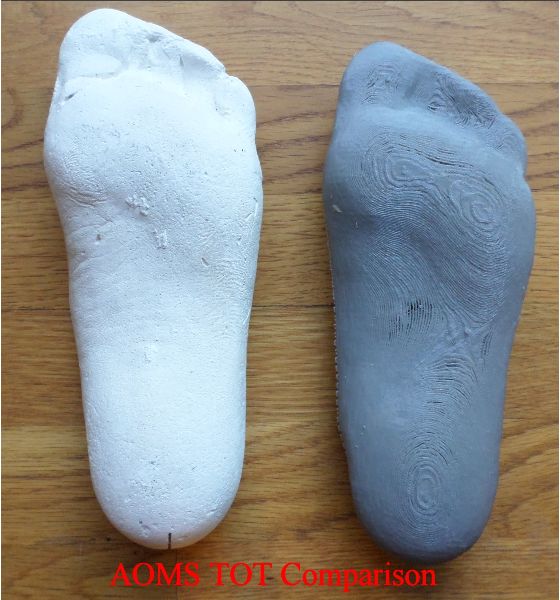

Real, wet plaster vs. imaginary, nonstick "plaster."

Why use AOMS TOT and not other approaches? Back to Titles

From the iPad foot scanner (iPad with the Structure Sensor and the AOMS TOT app) to the final product, orthotics, Sharp Shape’s AOMS provides a solid bridge. Why Sharp Shape and not others is because Sharp Shape has a long list of labs that are using the AOMS systems. Those labs are using AOMS systems to produce custom foot orthoses. Because AOMS systems are widely used in the orthotic labs, AOMS TOT finds its footings in the orthotic field.

Sharp Shape has a long list of labs that are using the AOMS systems.

AOMS TOT has extensive lab support.

What is the AOMS TOT iOS app about? Back to Titles

AOMS TOT app is a program that is used in the iPad to take 3D images of of the plantar surface of the foot, as well as the 3D images of positive and negative plaster-casts and foam-boxes. The AOMS TOT app is for podiatrists, chiropractors, pedorthists, shoe-store assistants and orthotic lab technicians. For simplicity, we sometimes call this combination of hardware and software "the 3D iPad Foot Scanner." It becomes a popular choice among foot scanning devices for making orthotics and shoe insoles. One of the main reasons of developing this package is its mobility. With the sensor attached to an iPad Mini, the scanner can be easily put into the pocket of a lab coat.

The iPad foot scanner is made of the iPad, the Structure Sensor and the AOMS TOT app.

The iPad app streamlines the process of naming, scanning, file-transferring all in one package, while it is simple enough for a trained office assistant to use and to avoid errors. Email and/or DropBox can be used as the carrier to transfer data, including a 3D OBJ file, a JPEG file and a text file containing necessary ordering information. The scanning dimensions are designed for feet in mind, to ensure highest resolution and accuracy with the sensor.

Many apps require the users to send files to dedicated companies. Our app does not limit you in this aspect. You can send files to your own email or DropBox, or to your supplier’s email or DropBox. It is a freedom. For your security/privacy, the AOMS TOT app was not programmed to send any information to Sharp Shape or to any person/business, except the recipients you intend to send to. We do not even know who are using it, because the purchase of the app is handled by the Apple App Store. We cannot audit you as the user and you are on your own. The AOMS TOT app is the number one choice among foot scanning apps for foot businesses.

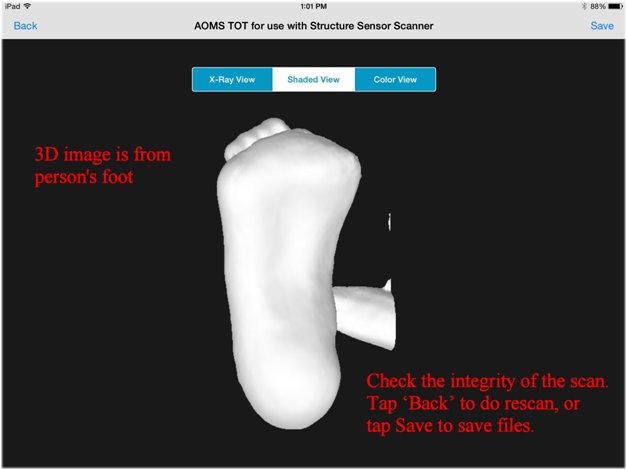

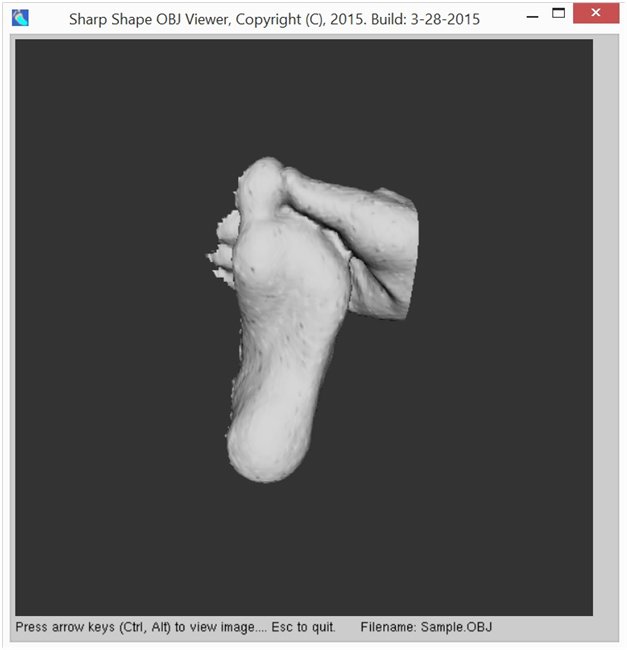

The AOMS TOT app captures the 3D image of the foot.

Our software is not used in the iPad scanner to play games or to make toys. Our software is used to make foot orthoses for the people in need. For the businesses that produce foot orthoses for their clients, our software products help you to make profits. Because the iPad foot scanner is versatile, it becomes a popular choice among podiatric and foot clinic 3D scanners.

What is the conversion/processing software about? Back to Titles

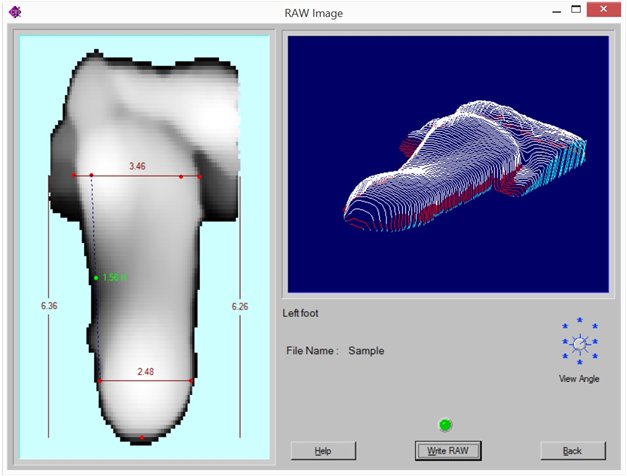

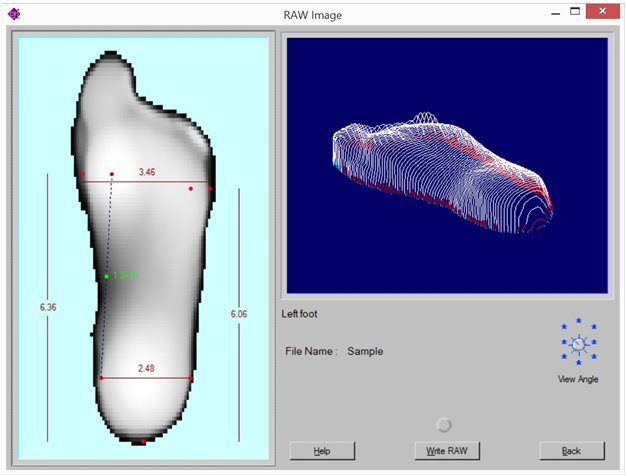

The iPad foot scanner creates OBJ files and the AOMS systems take RAW files. The RAW file format is Sharp Shape’s proprietary format. We need a software package to convert the files. That is what the processing/conversion program is for.

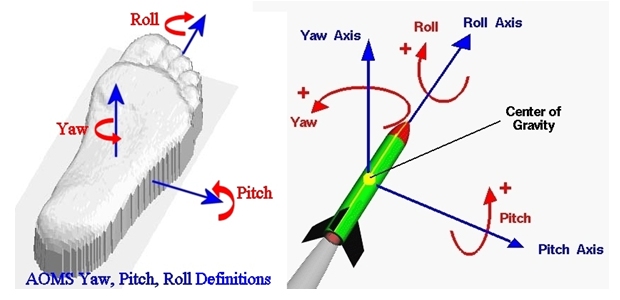

In the processing/conversion program, besides cropping and noise filtering, the program can make yaw, pitch, and roll adjustments, like our regular scan program does. Other rich processing functions are built in the program as well. These capabilities largely improve the quality of the images being fed into the AOMS systems. Together, they improve the quality of the final product: orthotics.

Sharp Shape AOMS Yaw Pitch Roll Definitions

Thumb and fingers can be left in the image if they are not in the way of cast correction. AOMS software has some ability to deal with artifacts.

Thumb and fingers can be left in image if they do no harm.

Thumb and fingers can be cropped out in the AOMS TOT processing/conversion program. These processed RAW images can be fed to the AOMS software to produce better orthotics.

Thumb and fingers can be trimmed out in the AOMS TOT processor.

You may wonder that if there are other conversion programs, why use Sharp Shape's? AOMS is the most popular automated orthotic production system. It reads our RAW files. Since we have not released the RAW file format, others have to go through reverse-engineering in order to get into AOMS. Because of the variables (some of them are floating numbers) used in the RAW file format, reverse-engineered RAW files may not be the same as the original RAW files. Besides, our processing/conversion program provides noise-cropping, yaw, pitch, and roll which have been implemented in our regular scan programs for years and many customers got used to them. These good features provide better images for the AOMS systems to process and to make better orthotics.

Orthotic labs need to have the AOMS TOT processor installed in order to make orthotics.

Why is our conversion/processing software the best? Back to Titles

As a tech company, we have serviced orthotic manufacturing customers for more than 20 years. During the years, we have set our feet in nearly 100 orthotic labs. We also have podiatrists providing us feedback. We know what customers need in terms of foot-image styles used in the AOMS cast correction software. Besides, we know better than anyone else for what the required file format is, because that is our proprietary file format used in AOMS systems. We do not have to reverse-engineer our file formats, because we know them. Reverse-engineered files do not work exactly the same as the original ones.

What is our history & views on the AOMS TOT project? Back to Titles

Throughout our history on this project, our first impression of the iPad scanner for scanning feet was that it is cute but not suitable, because we did not believe this tiny scanner could make wide-angle scans like our normal scanners do. We spent years in developing our own 3D laser foot scanner with a split-view through mirrors, which can catch the foot data around the lateral, medial, and heel. Second, we did not realize it is a laser scanner. It looks like a regular camera or due-camera setup. It actually has a Class I laser in it, while our scanners have Class II lasers. Our lasers are more visible, but they function similarly: to project a laser structure on the object. After we tested the iPad scanner, we found the iPad scanner can rotate around the foot during scanning and catch the data around heel and go beyond plantar surface with laser-precision.

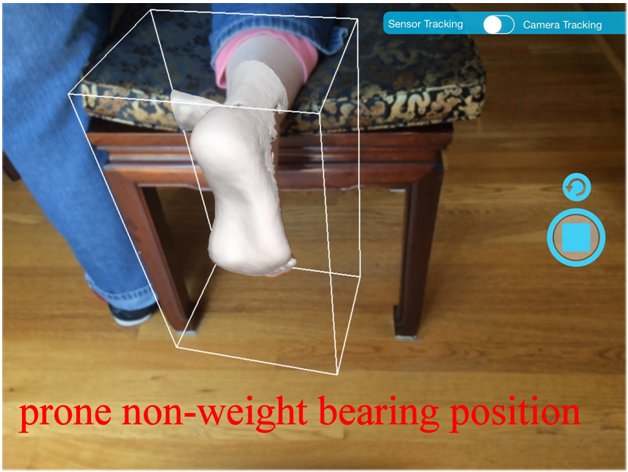

Scans can be made with supine or prone non-weight bearing positions.

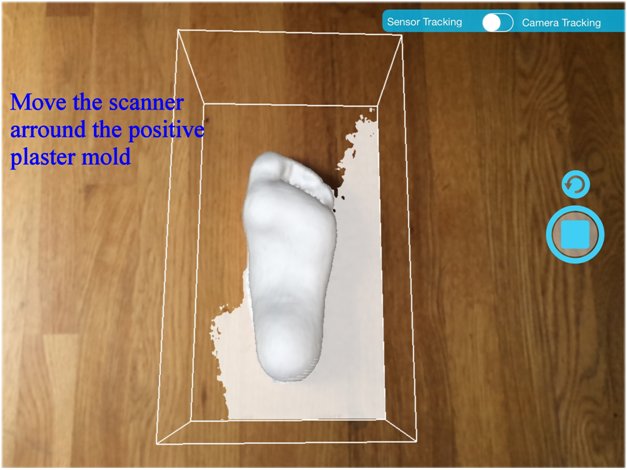

The little iPad foot scanner can not only replace the foot scanner, but also the cast scanner (certain rules to follow). It can scan positive plaster casts and negative plaster casts. In fact, it does a better job in scanning casts, because casts are stationary during the scanning process. The casts need to be laid on ground. The ground gives extra surface for more stable tracking.

Positive casts can be scanned.

The richness of the data is as good as a full size scanner, but the cost is significantly lower. The speed is slower though and neutral-position casting is a great challenge. At this stage, we hope AOMS TOT can replace foam impression boxes and we hope in the future it can do the work that neutral-position casting requires.

Negative foot casts and foam foot impression boxes can be scanned.

The image should be reviewed carefully before it is sent to the lab for fabricating orthotics. You can make a re-scan if you are not happy with the image, or you can send it right away by tapping a button.

During the scanning process, the foot image can be reviewed.

What are the major challenges to AOMS TOT? Back to Titles

The biggest challenge so far has been making scans with the foot in neutral position. Like with any new technology, issues and bugs can be greatly reduced with time and through hard work. For the moment, some customers have developed some simple methods, such as letting the patient to hold a rubber band or a stick to hold the sulcus of the foot in place.

A sulcus stick is being used in scanning a patient’s foot with the iPad foot scanner.

At Sharp Shape, we are not experts in foot biomechanics. Just from a better image point of view, the sulcus stick helps in the way that it makes it easier to make the scanner parallel to the foot during the scan. Without the sulcus stick, the foot plantar flexes and the scan is harder to make. The professional method for neutral position casting is that while holding the sub tailor joint neutral, use your thumb to fit under the sulcus of the 4th and 5th toes, and then with an upward and twisting motion you dorsiflex the forefoot to resistance. Please refer to the book "Neutral Position Casting Techniques," by Dr. Merton L. Root, et al. 1971. Although we are not on the gold standard yet, the sulcus stick makes it closer. You may use the sulcus stick in your own creative way. For example, you can hold the sulcus under the 5th and 4th toes.

Besides using assisting devices like the sulcus stick, scanning a foot in the neutral position with a two-person operation is an alternative. The following image is from the two-person operation.

Neutral position casting technique can be used with a two-person operation.

What are the Pros and Cons of AOMS TOT? Back to Titles

Although pros and cons of the AOMS TOT scanning approach have been addressed elsewhere in this website, we are listing them in a brief section for your quick reference.

Pros:

• seamlessly linked with AOMS systems

• comparable accuracy to our regular scanners

• mobile, portable, wireless, lightweight and versatility

• much lower cost than our regular scanners

• scans both feet and casts (negative and positive)

• 100% eye-safe Class 1 laser

• less light-sensitive, so less noise

• wide-angle scans (deep heel cup and ankle)

• no moving parts inside means easy maintenance and less maintenance cost

• less shipping cost than that of our regular scanner

• manageable file type (common .OBJ) and file size (usually 1 – 3 MB, not huge)

Cons:

• two hands are not free during the scan

• harder to make a neutral-position scan

• takes a longer time to make a scan

• a minimum distance of 0.4 meters (10.5 inches) is required

• scanner needs to move and rotate around the foot during scan

• more difficult to scan smaller feet

What are our efforts towards better images & orthotics? Back to Titles

Besides our efforts of creating a way for neutral-position casting (under development), we are improving the accuracy of this method. Please refer to the following photo. A positive plaster foot cast was scanned with the iPad foot scanner and the AOMS TOT app. Then the scanned OBJ file was used to produce a duplicate with a 3D printer, without modification in width, length and shape. The result shows that the length and width result does not come very close like in few millimeters, although the shape is maintained. We knew the material shrunk a little after it is printed.

We dare to compare, face challenges and do more work.

We realized that the iPad scanner with Structure Sensor is more of a depth scanner. The depth can be in a long range which can be several meters. In order to get more precise X, Y and Z results for our foot application, our AOMS TOT app has certain scanning rules to follow. Beside that, we did some experiments. We scanned a calibration object with precise width and length, and then we printed it with a 3D printer. Based on the result, compensations are made in our Windows conversion/processing program. We have not seen similar results from other companies. We are collecting more data for the compensation.

Why are not all iPad scanners made the same? Back to Titles

Do you know that not all iPad scanners are the same? The one we use is well equipped with laser and patented technology. Our AOMS TOT app creates 3D OBJ data files generated from the depth sensor (the Structure Sensor), not just from 2D JPEG files or from video clips taken through the regular iPad camera. By using the depth information, the 3D data is more accurate. The following illustration shows our 2D-to-3D scanner, a technology that we experimented on sometime ago. If the scanner can produce an acceptable result, the condition (surrounding light) has to be right. However, it is very difficult to control the condition. We believe another technology breakthrough is required for more accurate depth information extracted from 2D images or from video clips. At the current stage, the extra hardware with its cost is worthwhile, in order to get a more accurate 3D image result.

2D-to-3D scanner is not as accurate as the 3D iPad scanner yet.

Why not to create an app for the smartphone, like iPhone? Back to Titles

Apparently, smartphones are smaller than tablets, so why not? Although it is very appealing to make a smartphone foot scanner with the Structure Sensor, it has not become our priority for the following reasons:

• Without a phone contract, the smartphone is more expensive than a tablet. For example, an unlocked iPhone 5 is more expensive than the iPad Mini. To sell the smartphone foot scanner with a phone contract is hard to implement.

• The screen size is smaller so the keypad operation is harder.

• There are so many varieties of smartphones, even among the iPhone itself. Each requires a different setup. So it is hard to unify them.

• The current version of the AOMS TOT app does not have the color JPG function on an iPhone. This may reduce the interest from users.

In brief, we have implemented it on an iPhone 5 as an indoor R&D project, but we have not released it. We may follow that direction in future.

What are the cost comparisons on AOMS TOT? Back to Titles

Besides the small size, another good reason is its low cost. A full size 3D foot scanner costs about $2,500 (Sharp Shape’s initial price), which does not include the cost of the computer. The costs of other full-size 3D scanners may be higher than ours. On the other hand, the cost of the iPad Foot Scanner (iPad Mini + the Structure Sensor + AOMS TOT app), including the iPad (computer), the Structure Sensor, and the iPad app, is only around $800. We learnt that some labs even provide the iPad Foot Scanner free of charge if their client satisfies a minimum number of orthotics.

Labs need to get a starter kit of the conversion program from us with minimal cost. They will pay a conversion fee. Note that if labs choose to provide the scanning package, they add value to the final scanning/orthotic packages they provide to their clients and they should add their cost to it. Please contact the lab you choose directly for details.

How to start the AOMS TOT in action? Back to Titles

It is not hard to start the AOMS TOT. You need to integrate three major components: the iPad, the Structure Sensor, and the AOMS TOT app. We believe the best way to approach new technology is to test it. We recommend tests be made by iPad Foot Scanner users and the labs that host such users.

If you are a scanner user, you need to find an AOMS lab that has the ability to process/convert the images generated from the AOMS TOT app and make the orthotics for you. The procedures of implementing the whole system are described in the website: www.sharpshape.com/aomstot.html.

If you are an AOMS lab, you need to install the Windows processing/conversion program from Sharp Shape. This program is called the AOMS TOT processor. If you are not an AOMS lab and you want to be, you need to have AOMS installed in your lab. Please contact us for details.

What is ahead of us with AOMS TOT? Back to Titles

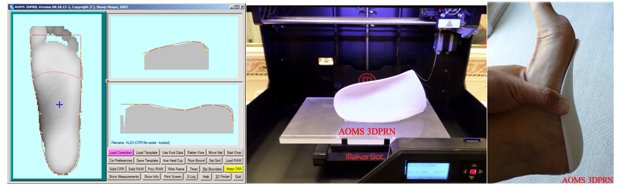

Do you know that you can use the iPad scanner to take foot images for AOMS 3DPRN? AOMS 3DPRN is a software package that makes foot orthoses through 3D printers. Information about AOMS 3DPRN can be found at: www.sharpshape.com/aoms3dprn.html.

AOMS 3DPRN software can be used to make orthotics through 3D printers.

How do we react to threatening technologies? Back to Titles

Sometimes, the emergence of a new technology, like the Structure Sensor, becomes a challenge or threat to our business. When facing "threatening" technologies, we treat our customers’ interests more importantly than our own interests, because we know if you are not successful, there is no room for us to exist. Since we make our own scanners, our scanner market faces their challenges. Should we help our customers with new technologies is an important decision we face. We took a lot of courage to start this project. Our hesitation came from the facts that we make our own full-size 3D laser scanners. If we start the project, it may gradually bury our scanner business. As stated, nothing is more important than customers’ interests.

Sharp Shape always innovates and stays at the very front of technology. The reason we decided to start with the project is that we think the project represents a new direction in the future and it is good for customers. We hope our decision for this project is correct. As time passes, we are getting more confident that this technology will prevail. If you ever want to try a portable, wireless tablet foot scanner in the future, give the AOMS TOT a try! Besides the advantages (many-lab support, no-audit app, and well-designed processing software) mentioned above, we are hard workers and we always support our products.

Note to the readers: Back to Titles

There are pros and cons with any new technology. If you are not convinced or hesitate to move on, we do not blame you and we can still help you. If you are not sure or do not want to take the risk, you may want to wait a little longer to see whether the technology can handle all the cases smoothly. If you are not convinced with the new scanner, you can still use our regular scanners since we still make and sell our regular full-size scanners now.

Please send us your feedback. More information will be added.

AOMS TOT System Requirements:

www.sharpshape.com/aomstot.html

Company website:

www.sharpshape.com

Company email:

sharpshape@comcast.net

Mailing address and phone number are shown below: