What's New in Sharp Shape?

<< Pioneers in Orthotic Automation Field >> (March 2024)

This is an article publised in www.aoms.me. If you are interested in the orthotic manufacturing history, you may want to read it.

We are excited to introduce our new AOMS TOT sr (Dec 2023)

This app is available now in Apple App Store. So what's good about AOMS TOT sr, compared with the previous AOMS TOT jr? Well, it is about scanning speed, tracking stability, broader device compatibility, and smoothness of data. This app can be used in our AOMS orthotic production systems. For this app, you must have an Apple device which has the TrueDepth camera inside. Ask us for more details.

Important Notice: AOMS TOT Compatibility with iOS 17 (Sept 2023)

If you are using the AOMS TOT app, please read the document named "Important Notice Regarding ST02 Sensor Compatibility with iOS 17". For your convenience, a PDF version and a JPG version are listed here. If you are not sure what hardware you are using, simply do not upgrade to iOS 17 yet. We will keep monitoring the development. Note that this Notice does not apply to the AOMS TOT jr app.

* AOMS TOT jr V6.0 - adding iPad Pro 11" (4th Gen) (April. 2023)

Using iPhone or iPad without external sensor attachment has many advantages. We understand that some users prefer iPad, instead of iPhone. Using iPad to scan foot looks more professional. Our recent AOMS TOT jr update Version 6.0 added the iPad Pro 11-inch (4th generation) in the compatible list.

* AOMS Foot Game (March 2023)

We just created an innovative video game. It is called 'AOMS Foot Game'. The purpose of the game is to help AOMS users to practice keyboard strokes which are used in the AOMS software. For details, please visit the Sharp Shape Video Game page. A sample view is shown below.

* Introducing AOMS Fit (March 2023)

AOMS Fit is a software program for designing custom foot orthoses for 3D printing. It is the second software package that we designed for 3D printing. Please read the introductory document and let us know if you have questions.

* AOMS TOT jr V5.0 - adding iPhone 14 in the list (Feb. 2023)

Using iPhone or iPad without external sensor attachment has many advantages. An iPhone has more advantages compared with an iPad because it it more portable. Our recent AOMS TOT jr update Version 5.0 added the iPhone 14 in the compatible list.

* Celebrating 30 years of making AOMS (Jan. 2023)

Sharp Shape started in January 1993. Since then, Sharp Shape innovated and popularized the AOMS (Automated Orthotic Manufacturing System). It has been 30 years till January 2023. Sharp Shape made a big difference in the foot orthotic manufacturing process. We will continue this endeavor.

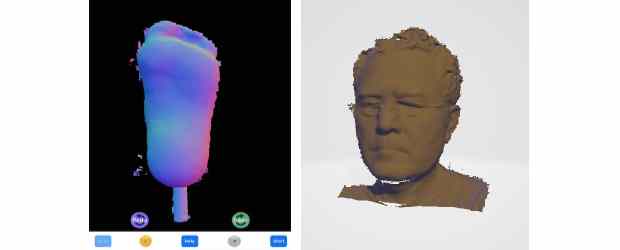

AOMS TOT jr major update – 3D viewing. Version 4.0 (June 2022)

In this update, we added the capability of 3D viewing of the foot , which includes Pan, Rotate and Zoom in the app. Before, users had to use a third party app to do that. This capability greatly improves the app. Take a look at the demos in iPhone and in iPad. Qualified devices are limited; please contact us for details.

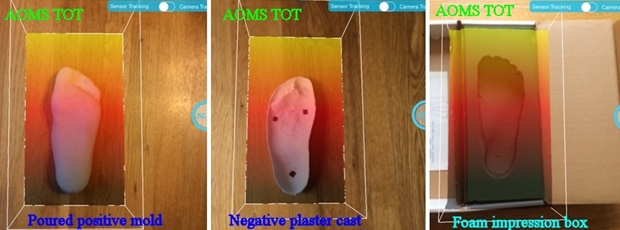

* Innovative way of scanning foot casts using AOMS TOT jr (Nov 2021)

We are now introducing an innovative way of scanning foot casts, either plaster casts or foam boxes, with the AOMS TOT jr. It is mobile, versatile and easier than ever. You can watch the Video. You need to turn on audio to hear instructions.

* AOMS TOT jr update. Version 3.0 (November 2021)

Using iPhone or iPad without external attachment has many advantages and it is still an attraction to many foot scanner users. Our AOMS TOT jr app is such an approach. There are challenges though. Apple makes new products quickly and we can barely keep up. We recently updated our app with more tested devices in it. Take a look at Apple App Store. Search key words ‘AOMS TOT jr’.

* Windows 11 is around the corner (October 2021)

As Windows 11 is just around the corner, we have tested our programs with it. The preliminary results show our programs are compatible with Windows 11. Further tests need to be made. Windows 10 will cease support in 2025. Both are good news to our customers.

* AOMS Video Game (April 2021)

We just created a fun video game. The purpose of the game is to help AOMS users to practice keyboard strokes which are used in the AOMS software. For details, please visit the Sharp Shape Video Game page. Update: we have the newer version 1.1.

* AOMS TOT jr update V2.1 B1.0 is available (January 2021)

This update solved the incompatibility issues with recent iOS like version 14.3. The new iOS made the app almost inoperable. The problem was that too few frames were processed. This update made the AOMS TOT jr app up-to-date. The advantage of using AOMS TOT jr is that it eliminates external sensor attachments. Information can be found here.

* AOMS TOT update V2.2 B1.0 is available (November 2020)

In Sept 2020, we reported that iPAD OS 14 caused an initialization issue with our AOMS TOT app and we suggested that you and your clients should hold the iPAD OS 14 update. Right now we have an AOMS TOT app update, which aims to solve this non-fatal, but very inconvenient issue. Some users have tested the update with their iPad OS 14 and found reasonable good results. If you want, you can update the AOMS TOT app from the Apple App Store. The current Version is 2.2, Build 1.0.

* Warning for the iPad scanner users (Sept 2020)

If you are using the original Structure Sensor or the Mark II or you want to buy a new iPad for it, we recommend that you do not update your iPad OS to version 14 yet. The hardware manufacturer is not quite ready to make them compatible yet. After they are ready and release their new SDK, developers begin to modify their apps. The new apps will go through Apple’s approval. It will take a while. This affects our AOMS TOT app users. We are monitoring this situation.

* Introducing AOMS TOT jr (August 2020)

Although AOMS TOT jr was released in the Apple App Store several months ago, we had not formally introduced it in our website since we felt we need to enrich it. Based on users’ feedbacks, our recent upgrades during the pandemic season expanded the functionalities of the app. Information can be found here.

* AOMS TOT app version 2.1 released (July 2020)

This upgrade of Version 2.1, Build 4.0 is to make the AOMS TOT App to be Apple's Files App compatible, so users can easily access the scanned files and share them through email or other methods at a later time. Some minor changes were made to improve the stability. AOMS TOT 2.0 and higher versions including this one are compatible with Mark II and with the original Structure Sensor.

* Introducing AOMS TOT Fit (May 2020)

During the past several months when the world was heavily influenced by Covid-19 pandemic, we have been busy in developing a new product. It is called AOMS TOT Fit. Now we have the first release of it. You can click on the link and check the information about it.

* Busy in R&D during pandemic (April 2020)

Sharp Shape always innovates. During each and every economic downturn in our 28-year history, we have more time to spend on our R&D and something new comes out, which changes the way we make orthotics. There is no exception during this coronavirus (Covid-19) pandemic season. Please check back to see the latest development.

* Our Privacy Notice Page (September 2019)

We have just set up a Privacy Notice page, concerning our App Store apps and our website. If you are interested, you can visit this Privacy Notice page.

* A sad shocking news (October 2018)

I just got a shocking news that Dr. Paul Robert Scherer, DPM, passed away. I met Dr. Scherer 27 years ago, before the AOMS was developed. The AOMS was developed along with the help of Dr. Scherer. He gave many suggestions from the aspect of foot biomechanics. He was the driving force of applying evidence-based medicine (EBM) criteria to choosing a foot scanner. Dr. Scherer wrote some books and many articles in his profession. With the sudden death of Dr. Scherer, I lost a mentor and a good friend and the industry lost a great leader. May Dr. Scherer rest in peace in heaven. – Alex Shang, Director of Sharp Shape.

* Cloud computing relating to AOMS (August 2018)

As ‘cloud computing’ is gaining its popularity, some customers asked us about it regarding the use of it in AOMS systems. Although we have not systematically worked on ‘cloud computing’, some information came to our minds but they are not enough. The critical issue now is that we have not heard of requirements clearly regarding using AOMS on cloud. These requirements must come from customers because they have such needs. Without the needs, we do not have to jump on the cloud. So if you have any needs relating to ‘cloud computing’, please let us know. So we will have the right direction to help you.

* AOMS TOT App has trouble to launch (solved) (March 2018)

Some AOMS TOT App users reported trouble to launch the app. The app quits immediately after it is being launched. The users have to do it for 3 to 5 times, in order to make a successful launch. We noticed this problem and contacted the Structure Sensor manufacturer. We learnt that the problem was introduced by an earlier iOS 11. The problem was reported to Apple. Apple recently released and update for the iOS 11, which solved the problem. If you have the same problem, you need to update iOS 11 on your iPad.

* Happy Holidays from Sharp Shape! (December, 2017)

Technology is moving forward. Apple created the iPad. Occipital developed the Structure Sensor for the iPad. How does this affect Sharp Shape? Well, "what's good for the goose is good for the gander." We developed the AOMS TOT foot-scanning app for the iPad and the Structure Sensor, which forms an iPad foot scanner. Although we call it a foot scanner, the scanner is versatile and it can scan bare feet, negative plaster slipper casts, foam impression boxes, and positive plaster casts. The scanner is small enough to be easily put into the pocket of a lab coat. Shipping costs and repair costs are lowered. Together with our back-end software for orthotic labs, many of our customers benefit from this technology. For this application, we have another 3D software, which will come out after the New Year. Take a good look at this animated 3D movie. Happy Holidays!

* Medicare New Rules Concerning EVA Insoles (November, 2017)

Recently, Medicare has changed their rules to include the direct-milled EVA insoles in their covered billing items. This is great news to many people. The biggest beneficiaries are the customers who are milling EVA insoles, especially those who are milling EVA insoles with three-head CNC machines, because of its high efficiency. Before this news, many people were in panic since some big changes were needed soon in their businesses practices. Sharp Shape was developing methods to use positive molds to make molded EVA insoles, in order to comply with Medicare's would-be new rules at that time. It would be painful anyway, because some automation means could not be directly used on insoles. Not anymore! We could be wrong in understanding Medicare. You can visit their website, or read this PDF document for details.

* It Is Time to Take a Good Look at Apple (July, 2017)

Throughout the 25-year history of Sharp Shape, we have almost always used PCs. Our AOMS programs are widely used in orthotic labs, on their PCs. With the recent development of Apple and its products, we feel it is the time to take a look at Apple. This Sharp Shape PDF document explains why. Our recent foot scanning approach is the AOMS TOT (iPad Foot Scanner). Introductory information can be found here and setup/tutorial information can be found here.

* New AOMS TOT app, version 1.7, was just released (May, 2017)

What’s new in this version? 1. A 2D foot image, as an option, can be attached to the file package. This image aids lab technicians in manufacturing foot orthotics. 2. Newer Structure Sensor SDK version 0.6.3 is used. 3. Newer Dropbox API v2 is used. 4. Add "cc" email address in settings to ease the work for users who need a second email address. 5. Corrected a few typos and weak points in the previous version 1.6. AOMS TOT app concentrates on: simplicity, efficiency, unlocked file format, and unlocked destinations for sending files. Visit AOMS TOT Page 1, or Page 2.

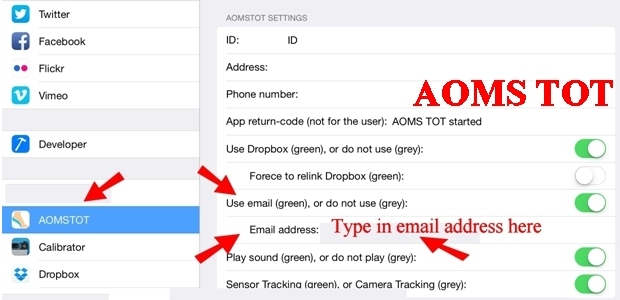

* AOMS TOT App Email Related Topics (February 2017)

Some AOMS TOT App users have questions regarding how to use email, especially how to enter a second email address to send images. The PDF document "AOMS TOT App Email Related Topics" explains email-related topics. You can click the document link or the illustration below to read the document.

* What is going on? (December 2016)

What’s new lately? Not much in the R&D field. However, we upgraded several old systems and set up a few new systems. Customers are our #1 priority. The photo (click here) shows a joint effort between Sharp Shape and Polh CNC, an authorized distributor for Freedom Machine Tool. The effort is to make three identical/simultaneous pairs of diabetic insoles on CNC router, and three rows can be scheduled together. It emphasizes quality, productivity, and durability.

* AOMT TOT Tutorial, Part 4 (August 2016)

A newly made AOMT TOT Tutorial, Part 4 is ready. It is an important episode, because it is based on feedback from iPad scanner users. Click here to see video. or click the following illustration.

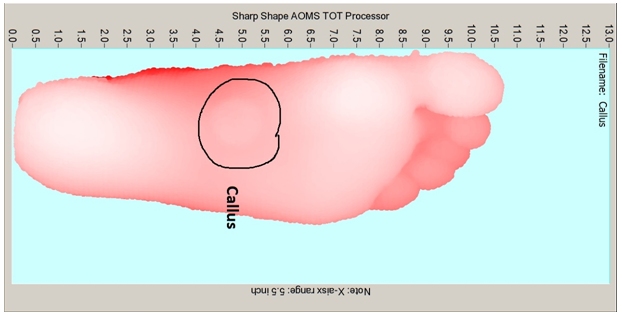

* Print Foot-Image in Real-Size (August 2016)

This is an experimental feature that we recently added to the AOMS TOT Processor software. For more information, please visit this page or click the following illustration.

* AOMS TOT MILL - a new production process (July 2016)

AOMS TOT MILL is a new automated orthotic manufacturing process. It emphasizes simplicity with the latest new technologies. Click the AOMS TOT MILL info page for details. Our current research and development revolve around new technologies, i.e. the iPad scanner, 3D printer and AOMS 2.0 software.

* Improved AOMS TOT processing/conversion software (Jan. 2016)

The original AOMS TOT processing/conversion software was intended to process and convert files generated from scanning feet using the AOMS TOT app. Some customers asked us to include other files generated from scanning negative casts (plaster casts and foam boxes) and from scanning positive casts (poured plaster molds). We recently made such improvements. These functions are available in software version 2.3 and above. Imagine that! A low-cost, handheld 3D scanner replacing both the 3D foot scanner and cast scanner all together. Note: guidelines of scanning casts need to be followed. Refer to the info page or the link for setup and tutorials.

* What was new in Year 2015? (December 2015)

Ow! Time flies by so fast. Although swamped with daily work, two important R&D projects were implemented in 2015. The AOMS TOT has been out of beta-testing. The AOMS 3DPRN is still in beta-testing. If you google low-cost iPad 3D foot scanner, you will w-w-w.s-h-a-r-p-s-h-a-p-e.c-o-m. When you w-w-w…, you will find the amazing AOMS TOT which lowers your scanner costs. Sorry for the poor grammar, but it works. Together with our 3D printer package (AOMS 3DPRN), AOMS TOT provides you a personalized benchtop AOMS (Automated Orthotic Manufacturing System).

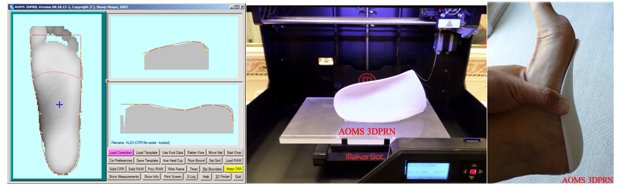

* Introducing AOMS 3DPRN - 3D printer software (Sept. 2015)

3D printers have caught the attention of people from all walks of life for several years now. After the initial excitement, the matter calmed down a little because of the bottleneck in speed and limited choice in materials. A lot of 3D printers are currently used in creating toys and souvenirs only. Instead of waiting for another breakthrough, we are releasing the orthotic-design software, hoping some companies out there have better solutions for faster speeds and more suitable materials. Technologies are surely improving. Sharp Shape has been concentrating in the practical use of 3D printers for foot orthotic production for some time. The software package that we created may help you to turn your 3D printer from a toy-maker to a profitable workhorse. It is still in the beta testing phase. For information about it, please visit: AOMS 3DPRN System Information, or click the photo below.

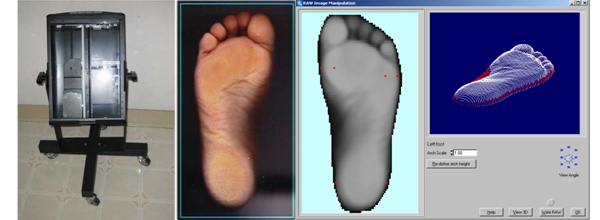

* When iPad 3D scanner meets AOMS®: AOMS TOT (Aug 2015)

AOMS TOT™ is a technology package, which includes a small 3D laser scanner named Structure Sensor, a customized Apple iPad app named AOMS TOT, and a Windows processing/conversion program designed for labs to convert OBJ files to RAW files. RAW files can be used in the AOMS systems to produce orthotics in many labs around the world. For easiness of discussion, we will call the scanner made for the iPad the Structure Sensor and the AOMS TOT app the iPad Foot Scanner. The movement goes towards mobility and low-cost. Although there are some obstacles (the largest one being the neutral position casting), this technology represents a new direction for foot scanning in the future. For system descriptions, please click the link AOMS TOT System Information or the photo below. For system requirements and tutorials, please visit www.sharpshape.com/aomstot.html.

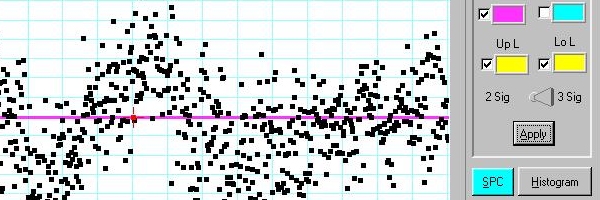

* Introducing AOMS SPC (July 2015)

If you are a lab owner or a lab manager using the AOMS® system, it's very likely that you want to control the quality of orthotics made from the manufacturing process. If you are a lab technician using the AOMS® system, it's likely that you have corrected thousands of foot casts. These files contain your expertise in orthotic designing. You want to make sense out of them, but how? There were no better tools until now. AOMS SPC is a Windows-based program that utilizes the SPC principles on the COR files generated from the AOMS® systems. Click here to view more details: Introducing Sharp Shape AOMS SPC.

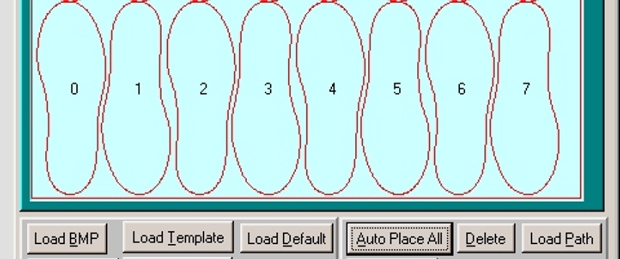

* Introducing AOMS INSO TRIM (July 2015)

It is not easy to draw insole boundaries freehand, even with a template at your side as reference. Just assume you have drawn a perfect boundary shape you like, how do you scale them into different sizes? Further assume you have made a set of good ones with different sizes, how do you carry them out to produce real insoles with EVA, vinyl, or cork? Hydraulic punchers can be used, but it is heavy equipment, and steel dies are expensive to produce and to modify. Let’s assume you can produce the desired insoles, but how do you modify them if there are needs for change? With the AOMS INSO TRIM and the CNC machines, you can put those dreams into reality. Click here to view more details: Introducing AOMS INSO TRIM.

* Introducing AnyFoot from Sharp Shape (July 2015)

We have finished the R&D on AnyFoot a couple of years ago. Because of the very nature of this project, we considered it was confidential and kept it as "classified." With the advances in scanning technologies, and with the emergence of many type of scanners, we will declassify this project now. This project has been out of beta testing. Update: a much better choice is the AOMS TOT (Aug. 2015). If you are interested in AnyFoot anyway, please contact us for details. Click here to view more details: Introducing AnyFoot from Sharp Shape - Brief.

* Article in Podiatry Management, Page 136, issue of January 2015

This is an article which explains the methodology that we used in our AOMS systems. It is very informative by providing details about the technologies that we use. Here is the article: Sharp Shape Profiles In Excellence Podiatry Management Page 136 January 2015.

* Sharp Shape Scanners Used with Apple Computers (Jan. 2015)

Our USB scanners were designed to be used on PCs with Windows. Some customers asked for the possibility of using an Apple computer. Our current successful trial was based on Apple’s Mac Mini, OS 10.10 Yosemite. For our use, we need to do a “boot camp” on the Apple computer. In theory, besides Mac Mini, any Apple computers with Intel processors can be used for our purpose, but more experiments need to be made. For details, please contact us. Click here for the photo.

* New colors to our foot scanners (November 2014)

Besides our regular black color, we have added beige and gray colors to our foot scanners. Motivated by the feedback from our customers, we recently added these color options to our foot scanners. Click the picture below to see details. Click here for the photo showing two colors.

* Foot Scanner Ordering System (July 2014)

We have just introduced an orthotic ordering system for our foot scanner users. This product makes orthotic ordering through the Sharp Shape scanners as easy as 1-2-3. Click here for the screenshot.

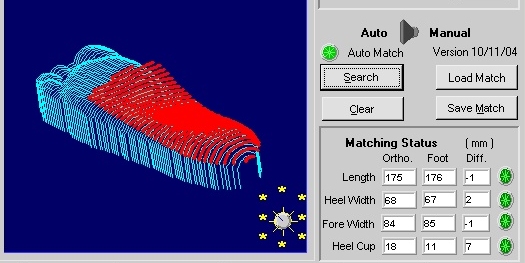

* Foot Orthotics Matching System (June 2014)

With the recent developments and improvements in our foot matching system, we are re-introducing the Sharp Shape Foot Orthotic Matching System (FOMS™) to you. Tens of thousands of COR files (cast correction files) cannot be fully utilized until now. Click here for a screenshot.

* Created Investors page (April 2014)

Click the Investors tab to find more information.

* Created AOMS Participating Labs page (Feb. 2014)

Click the Labs tab to find or to join AOMS Participating Labs.

* Created 2 tutorial video clips. We will add more. (Feb. 2014)

Click the Products tab and navigate to the end of the page.

* Created the Hands-on kit to make website user-interactive (Jan. 2014)

Click the Gallery tab and scroll down to the end to review the 3D objects that we created.

* We just digitally signed our scanner software drivers (Dec. 2013)

Click the Downloads tab and find the Signed Drivers Section.

* We did R&D on 3D Printer / some customers asked for it (Dec. 2013)

Click the R&D tab and find more.

* We poured a lot of technical information into Downloads (Oct. 2013)

Click the Downloads tab and find out.

* AOMS® trademark registered with USPTO (May 2013)

AOMS stands for "Automated Orthotic Manufacturing System," and is designed, made and integraded by Sharp Shape. AOMS® is a registered trademark of Sharp Shape.

* Celebrating 20 years of making a difference (Jan. 2013)

While celebrating the 20th anniversary in January 2013, Sharp Shape became a fine "man" at its prime. Compared with the way the foot orthoses were made 20 years ago, the difference that Sharp Shape made in the foot orthosis manufacturing process is monumental. Sharp Shape has set up 84 AOMS™ systems around the world, with 50 in the United States, 23 in Canada, 4 in Australia, 1 in New Zealand, and 6 in Europe. These counts do not include scanner sales. AOMS™ is the backbone of orthotic labs. Tens of millions of foot orthoses were made through the AOMS™ systems with no royalties charged. To see the difference, click: Sharp Shape Difference.